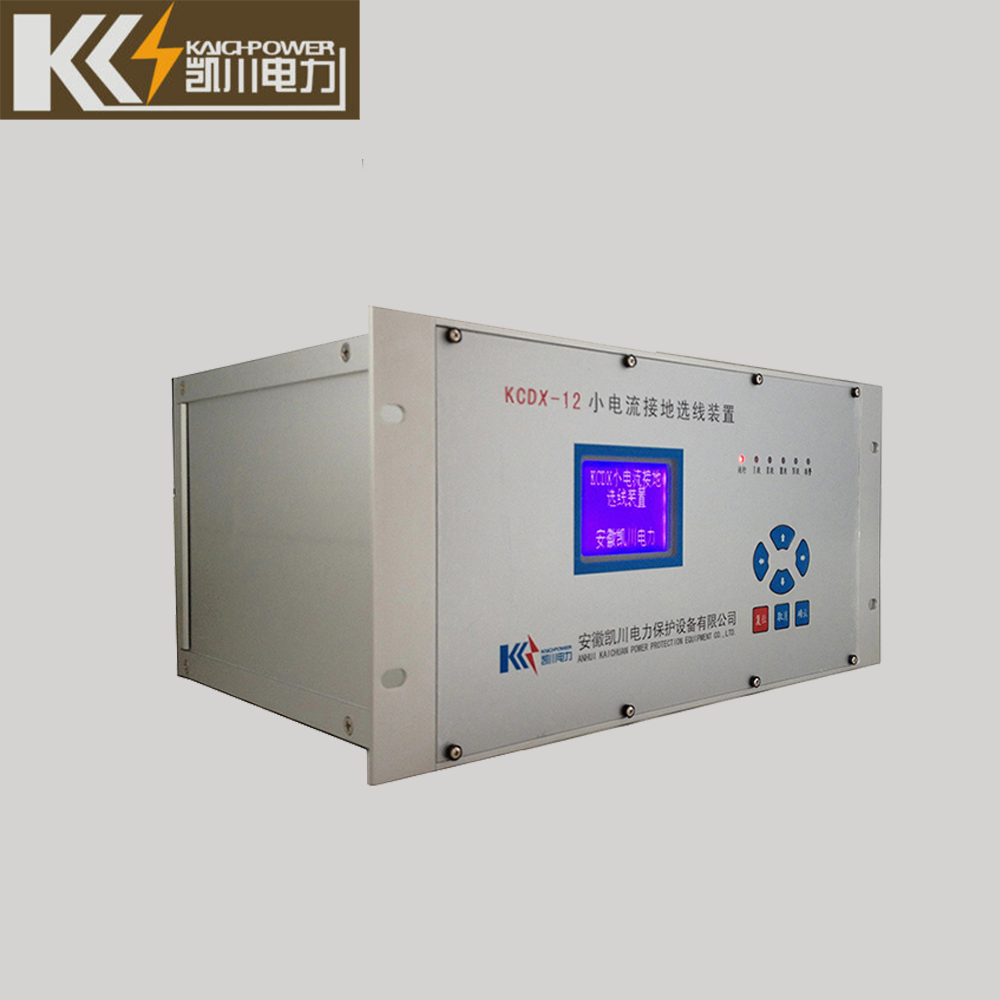

Small Current Grounding Line Selection Device

Single-phase grounding is the most common fault in medium-voltage distribution networks. Although the grounding system can continue to operate with faults, due to the rise of non-faulty relative to ground voltage, if not dealt with in time, it may develop into non-faulty phase insulation damage secondary to phase-to-phase. Threat of short circuit. Timely and accurate determination of grounding loop is the basis for quickly eliminating single-phase grounding faults.

KAICH applies the new concept and new method of microcomputer measurement and control technology, and develops KCDX series intelligent low-current grounding system grounding line selection device for analog signal processing and A/D conversion, breaking through the first problem of “line selection accuracy”, making The result of line selection really has practical value.

Application

- Suitable for small current systems where the neutral point is not grounded

- The maximum four-segment bus system, the total outgoing circuit is not more than 48 circuits (special instructions are required when thinking about 48 circuits)

- Widely used in power system substations, power plants and large-scale mines such as coal mines, partial iron, metallurgy, chemical industry, etc.

The device monitors the zero-sequence voltage of each segment of the system and the zero-sequence current of each outgoing line in real time. When a ground fault occurs in the system, the device calculates and analyzes the magnitude and phase relationship between the zero-sequence voltage at the open triangle of the grounding bus PT and the zero-sequence current of the bus outlet. Line, at the same time display, record, remote transmission of relevant fault data, give warning signals, and then maintain the cycle monitoring state

1. Power supply voltage: AC220V±10% or DC220V±10%;

2 Power consumption of the whole machine: ≤20W;

3. Ambient temperature: 10℃+55℃; air relative humidity: no more than 90%

4. Environmental requirements: There is no conductive dust or corrosive gas mold that damages the insulation in the surrounding medium. The installation site should be protected against wind, rain, sand and dust.

5. Input parameters: voltage level: 1-2, bus segment number 1-4, outlet number: 12, 24, 36, 48

6. Zero sequence voltage (PT1-PT4): 100V, zero sequence current (CT1-CT48): 0.5A

7. Communication: interface RS232 interface, RS485, RS422 optional, default RS485 interface, communication protocol Disa, Moudbus, XJ103 optional

8. Alarm output: alarm relay contact capacity is DC220V, 5A

Feature

1. The core components of this device use a new generation of intelligent ARM chips, with high integration, strong anti-interference ability, fast running speed, large storage capacity and high reliability

2. Using dual ARM chips, independent ARM chips are used for data acquisition and analysis and judgment

3. Input zero-sequence current does not have the same name terminal

4. Adopt large-screen LCD LED display

5. There are two output modes of alarm and coding

6. Equipped with RS485, RS232SRS422 multiple communication interfaces

7. It can be memorized and can store 30 times of grounding fault information, and the information will not be lost after the device is powered off

8. The on-site CT is variable, and the starting voltage can be set by software, which does not need to be adjusted on site and has perfect self-checking and self-recovery functions.