Smart Grid Monitoring Device

samrt grid monitoring device is the latest product developed by Kaich for three-dimensional and all-round monitoring of high-voltage switchgear. It can simultaneously replace the intelligent control device and monitor the temperature of the cable contact surface, fault arc light signal, cable insulation, power quality, smoke detection, partial discharge. Abandoning the limitations and incomprehensibility of traditional monitoring of a single feature quantity, and taking into account the necessity of monitoring.

Smart Grid Monitoring Device of Contents

Overview

1.1 Necessity of Temperature Rise Monitoring of Switchgear

In the high-voltage switchgear, due to the dual action of contact resistance and long-term aging, the contact resistance of the busbar joint contact switch, knife switch, and other important equipment joints is likely to further increase the contact resistance, resulting in serious heat generation and temperature rise. If it is not found in time, it will easily lead to equipment burning failure. Affect the safety and reliability of power supply.

It is not allowed to open the measurement temperature during the operation of the high-voltage closed switchgear. Traditional infrared handheld temperature measurement cannot achieve 24-hour real-time monitoring and alarm. The key to solving the problem is to realize the online monitoring and early warning of temperature. Eliminate power supply hidden dangers in time to prevent accidents.

“State Grid Corporation’s Eighteen Major Power Grid Anti-Accident Measures” State Grid Biotechnology [2005] No. 400 document clearly pointed out that: to prevent overheating of the current-carrying circuit of switchgear, regularly use temperature measuring equipment to check the electrical conductivity of switchgear joints and isolation switches. Parts (key parts: contacts, outlet sockets, etc.), especially during heavy load or high temperature periods, strengthen the monitoring of the temperature rise of operating equipment, and take timely measures if problems are found. Online temperature monitoring is indispensable to the safety and reliability of power supply, but simple temperature monitoring cannot achieve comprehensive protection and timely self-handling of accidents. Our company’s creative arc light technology is introduced into this system. The dual functions of monitoring temperature and arc light can be achieved, and the fault point can be removed. Keep faults to a minimum.

1.2 Necessity of Arc Monitoring

In my country’s medium and low voltage busbar short-circuit faults, the main equipment and personnel injuries are mainly caused by arc light. However, most of the medium and low voltage busbars in my country are not equipped with fast busbar protection, but only simple arc suppression devices and transformer backup protection are used. These protections have low intelligence and slow action speed, which often prolongs the fault removal time, thereby further expanding the degree of equipment damage, and even causing a vicious accident of “burning the company”, which affects the safe operation of the entire power grid after one-time operation of the transformer.

The arc protection unit of the cable head explosion-proof device is our company based on the actual situation in China, absorbing the characteristics of foreign arc protection, combined with the relevant regulations of industry testing and protection configuration, and independently issued a unique innovative technology, with a wide range of practicability and high reliability. New arc protection system. It adopts the principle of double criterion of arc detection and overcurrent detection, and has the characteristics of fast protection action and high reliability.

The power of the short-circuit arc in the switch cabinet can be as high as 100MW. The energy generated by the arc combustion increases exponentially with the arc’s burning time and short-circuit current change value (as shown in the figure below). The high temperature and high pressure generated by the combustion will gradually destroy Components, copper bars and rows of switch cabinets, high-brightness arc light and toxic gases also cause great harm to the human body.

To keep the device free from structural damage, the resection time must be kept as short as possible.

1.3 Necessity of Cable Insulation Medium Monitoring

Online monitoring of cable insulation medium is a kind of measurement of characteristic parameters of power equipment using system operating voltage under the operating state of power equipment. Measurements can be continuous or intermittent. On-line monitoring is a non-destructive measurement. Since the measurement is carried out during the operation of the equipment, the authenticity and effectiveness of the test are greatly improved, and it is helpful to discover potential defects and faults of power equipment in time.

For the online monitoring of high-voltage power cable insulation, there are many methods at present, but each monitoring method has shortcomings, each of which is difficult to fully characterize the insulation status of the cable.

The cable insulation monitoring module developed by our company is a technical means based on monitoring the leakage current, dielectric loss tangent, equivalent capacitance and other insulation indicators for the neutral point ungrounded high-voltage system. It integrates the advantages of various monitoring technologies and effectively The measurement errors caused by harmonics and sensor zero drift are eliminated, and the measurement accuracy and stability are improved. On the hardware, high-precision micro-current sensors are used to detect the leakage current of high-voltage power cables, and the voltage signal is extracted from the secondary side of the voltage transformer. The technology effectively solves the problem of accurate measurement of dielectric loss and resistive current in the on-site interference environment, and has high measurement accuracy and strong anti-interference performance.

1.4 The Need for PD

When partial discharge occurs in the high-voltage switchgear, a current pulse with nanosecond steepness will be generated. Excited electromagnetic waves with a wide frequency band. UHF detection sensors (ie UHF sensors, TEV sensors and HFCT sensors) detect the high frequency electromagnetic wave frequency band (300MHz-2000MHz), which can effectively avoid the reliability of corona interference and power frequency interference of the switch cabinet. High, strong anti-interference ability. It is sensitive to various partial discharge types, and the sensitivity can reach several PCs.

UHF sensor, TEV sensor and HFCT sensor adopt non-contact monitoring, which does not affect the normal operation of the equipment and is safe and reliable. The UHF sensor developed by our company adopts an integrated design, that is, receiving, collecting, calculating and integrating, so as to avoid the loss of high-frequency signal transmission. The PD acquisition device adopts narrow-band filtering technology, fuzzy algorithm, fast Fourier transform, periodic grouping, class database matching and other algorithms to eliminate various disturbances on site.

1.5 The Need for Smoke

Mainly monitor the indoor smoke alarm of the secondary instrument.

1.6 Power Quality Monitoring

This device is mainly used to measure and analyze the AC power quality supplied by the public power grid to the user.

The device can pass the class IV electromagnetic anti-interference type test of the national testing center. At the same time, the communication protocol can pass the national-level communication and protocol inspection to ensure that the device is compatible with the entire monitoring system.

The controller design refers to the following standards:

National standard | “Technical requirements for arc protection devices” | GB/T 14598.302-2016 |

Energy Industry Standard | “Guidelines for Selection of Arc Protection Devices” | NB/T 42076-2016 |

Electric power industry standard | “General technical conditions for arc protection devices” | DL/T1504-2016 |

Energy Industry Standard | “Technical Requirements for Wireless Temperature Measurement Devices” | NB/T 42086-2016 |

Relay protection standard | “Code for Design of Relay Protection and Automatic Devices of Power Installations” | GB50062-92 |

2. Scope of Application

This device is suitable for various voltage levels from 3KV to 66KV, and can monitor, process and analyze common faults in the power system in real time. It can be widely used in the power supply system of substations, power plants, hydropower stations and large-scale factories and mines such as chemical industry, oil extraction, metallurgy, coal, railway, etc.

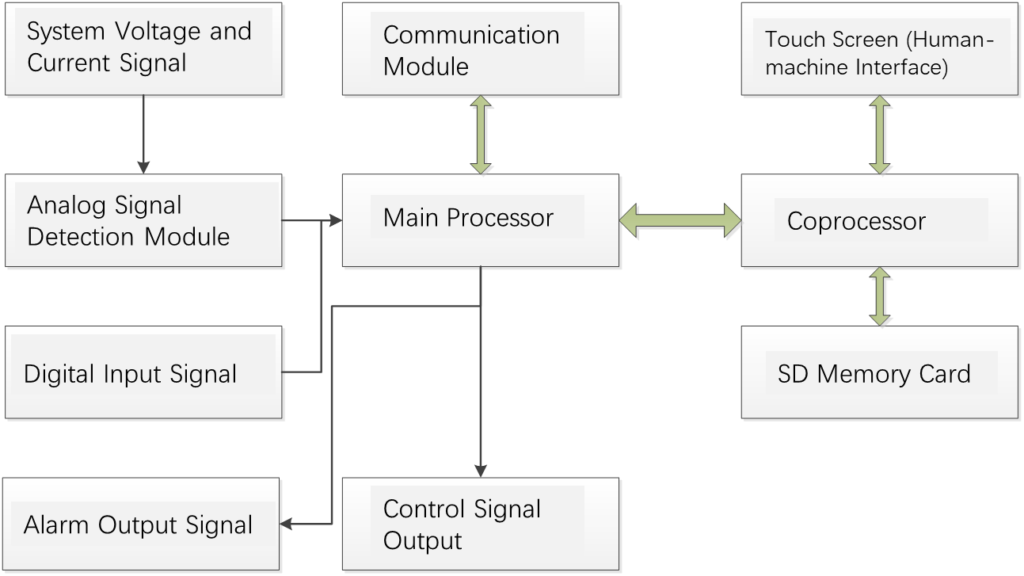

3. Working Principle

The device consists of power supply module, analog signal acquisition module, digital signal input module, relay signal output module, switch value acquisition module, main processor module, coprocessor module, communication module, SD card storage module and other parts, as shown in the figure:

The controller collects system voltage and current signals, external feedback signals and feedback signals from other devices, monitors the operating conditions of the power system and the device itself in real time, and displays it on the user interface in real time. When various types of faults occur in the system, the types and attributes of the faults are quickly analyzed, and corresponding processing is made according to the judgment results.

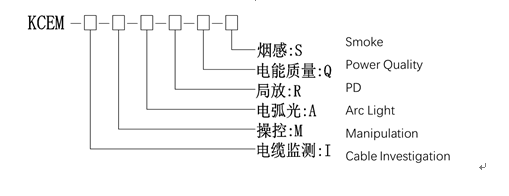

4. Selection instructions

After selecting “Parameter Setting”, you will be prompted to enter the corresponding password, the factory password is “0000”, enter the correct password to enter the parameter setting menu.

5. Functions and Features

1) Stereoscopic all-round monitoring

The device adopts three-dimensional and all-round monitoring of functions such as power quality, arc light, temperature, cable insulation, partial discharge, smoke detection, and control, and compares the signals of various sensors horizontally to ensure the accuracy of monitoring.

2) “Multi-criteria” maggot trip protection

The device has a flexible combined trip protection function, which can realize single criterion, double criterion and multiple criteria.

Single criterion: arc single criterion trip protection function;

Double criterion: arc light + temperature double criterion trip protection function;

Multi-criteria: arc light + temperature + current + insulation multi-criteria trip protection function.

3) All-round signal alarm protection

The device monitors any abnormal signal of power quality, arc light, temperature, cable insulation, partial discharge, and smoke alarm, and quickly sends out an alarm signal and uploads it to the background system, so that the on-site personnel can locate the fault point in time and quickly troubleshoot the fault.

4) Full digital visualization interface

The device adopts full digital design, flexible configuration, high action accuracy, and eliminates the hidden error caused by knob or other mechanical design.

5) Friendly human-computer interaction

Industrial-grade LCD screen display, friendly man-machine interface, full Chinese menu, full touch screen.

6) Sensor self-powered technology

The temperature sensor of the device adopts maintenance-free self-charging technology, which does not require frequent batteries, reduces maintenance costs and improves service life.

7) Comprehensive record and storage of fault information

The device comprehensively records and stores fault signals, with a maximum storage capacity of 200.

6. Technical Environment Parameters

Device module | Function | technical parameter |

Auxiliary working power | Power Supply | AC/DC 85V-265V/50HZ |

Input Error | -20%- +15% | |

Power Consumption | Normal operation 10W, device action 15W | |

Current input | Rating In | 5A |

Measuring Range | Protection current: 0~20ln | |

Measurement Error | Protection current: <1% | |

Power Consumption | <0.5VA | |

Protective function |

| <5ms |

input interface | Current Signal Input | Optional 1 group (three-phase current) |

Arc Signal Input | Standard 1 channel | |

Temperature Signal Input | Standard 6 channels (expandable to 12 channels) | |

Isolated Signal Input | Standard 1 channel | |

PD Monitoring | Optional 1 channel | |

Smoke Detection | Optional 1 channel | |

Output Interface | Alarm Signal Output | Standard 3-way (spare 2-way) |

Trip Signal Output | Standard 1-way (spare 2-way) | |

Communication Interface | Communication Interface | Standard 1 channel RS485 |

Isolation Type | Photoelectric isolation, with lightning protection function | |

Baud Rate | 1200bps-9600bps | |

Communication Protocol | Modbus |

Application Environment | Parameter |

System Voltage | 0.4kV-10kV |

Normal Operating Temperature | – 10°C~+55P |

Storage Temperature | -25°C~+70°C |

Relative Humidity | 5%-95% |

Atmospheric Pressure | 60kPa-106kPa |

Protection Class | IP50 |

Filth Level | < level II |

Altitude | W2000 meters |