Overview

The power system is rapidly evolving toward a large-scale grid with high reliability and advanced automation. The automation level and intelligent monitoring of power grid operations have become crucial issues of great importance both domestically and internationally. As society’s power consumption continues to increase, there is a corresponding rise in power loads on high-voltage electrical equipment such as transformers, high-voltage switchgear, and outdoor knife switches, which are responsible for transmitting heavy loads.

Much high-voltage electrical equipment within the power grid, as well as the connection points between these equipment, represent the weakest links in power transmission. The primary issue associated with these weak links is the generation of heat at the connection points. As the load increases, the connection points experience elevated temperatures, leading to a vicious cycle: temperature rise, expansion, contraction, oxidation, increased resistance, and subsequent temperature rise, eventually culminating in accidents. Consequently, the power system invests significant manpower and financial resources to implement various measures aimed at monitoring the temperature increase at high-voltage connection points.

Necessity

For a long time, it has been difficult to monitor the operating temperature of connection points in high-voltage equipment in real-time online. This is because these areas are exposed to high voltage or confined spaces, and conventional temperature measurement methods cannot be used due to the inability to address high-voltage insulation issues. Wireless temperature measurement devices utilize radio waves for signal transmission, with sensors installed on the high-voltage equipment and no electrical connection with the receiving device. Therefore, this system fundamentally solves the challenge of real-time online monitoring of operating temperatures at connection points in high-voltage equipment.

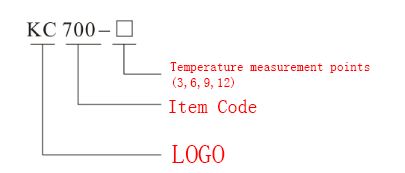

The KC700 electrical contact wireless temperature measuring device offers exceptional reliability and safety. Its affordable price allows for installation on busbar connectors, outdoor switches, or transformers within each high-voltage switchgear. The system is equipped with a standard communication interface and can be integrated into a network. By connecting to a host computer, real-time operating temperature data of high-voltage equipment can be recorded. The device also incorporates a robust alarm mechanism that triggers alerts for strict temperature rise and rate of change, enabling cumulative data collection for high-voltage equipment maintenance and facilitating predictive maintenance for thermal failures of high-voltage equipment.

Advantage

The KC700 electrical contact wireless temperature measuring device is specifically designed for real-time monitoring of the operating temperature of high-voltage charged bodies. The system incorporates state-of-the-art wireless technology design, including special wireless coding technology, which provides strong anti-interference capability and enables long-distance transmission. It is the first of its kind developed in China and allows for remote telemetry of high-voltage electrified body temperature.

This product boasts excellent sealing performance, making it suitable for safe use both indoors and outdoors. The system offers several advantages, including low power consumption, equipotential measurement, wireless data transmission, high precision, fast response time, flexible operation, and convenient networking capabilities.

Technical features and advantages of KC700 electrical contact wireless temperature measuring device

- The transmission adopts the frequency of 433.92MHZ and works in the free frequency band

- Digital temperature sensor, accurate and accurate measurement range

- Built-in antenna, small size

- Extremely low sensor power consumption (≤10mW), battery life: >5 years

- Up to 65535 wireless sensor addressing

- Automatic sensor identification, no connection, easy installation

- Temperature measurement signal data transmission method: wireless transmission, long transmission distance (200 meters in open area), strong penetration; (traditional infrared and 2.4G communication frequency bands have short transmission distance, poor penetration performance (V=λ *f))

- The product has a wireless anti-collision function and high receiving sensitivity

The main equipment of this product features a user-friendly interface with a color screen display, providing an exceptional visual experience. It includes a background picture, ambient temperature and humidity display, as well as real-time monitoring of the actual temperature value of the electrical contacts. Parameters can be customized according to customer requirements, and there are two output protection nodes for early warning and alarm. Additionally, it offers an environmental temperature and humidity load output node.

The transmitting module of this product is made of high-performance insulation material with excellent temperature resistance. The main equipment is designed with a flame-retardant shell and flame-retardant circuit board. The sensor is equipped with shielded and high-temperature wires.

The transmitting module consumes low power, with static power less than 5uA and less than 6mA during transmission. The transmission frequency varies depending on the site conditions and generally occurs every 90 seconds after the temperature stabilizes. For specific users, the transmission frequency can be customized to meet their requirements.

- The electronic circuit of the main equipment is equipped with over-current protection, over-voltage protection, and measures for electromagnetic compatibility and anti-interference. These ensure the safe and stable operation of the product.

Three temperature measurement technologies are compared:

The technologies used to monitor the operating temperature of high-voltage equipment contacts mainly include infrared temperature measurement, optical fiber temperature measurement, and wireless temperature measurement.

Comparison of wireless and optical fiber temperature measurements:

- The optical fiber temperature sensor uses optical fiber to transmit temperature signals. The optical fiber has excellent insulation properties and can isolate the high voltage in the switch cabinet. Therefore, the optical fiber temperature sensor can be directly installed on the high-voltage contact in the switch cabinet to accurately measure the operation of the high-voltage contact. Temperature, to realize the online monitoring of the operating temperature of the switchgear contacts. However, the surface of the optical fiber used to isolate the high voltage may be contaminated, which will cause the surface discharge of the optical fiber. This limits the temperature measurement application of the optical fiber temperature measurement system for outdoor switchgear. The wireless temperature measurement system uses electromagnetic waves to transmit signals. The sensor is directly installed on the high-voltage equipment. The temperature measurement is accurate and can completely solve the electrical insulation problem. The wireless temperature measurement system is not affected by the climate environment and can measure any high-voltage charged body indoors and outdoors—the temperature at the point where there is a temperature accident hazard.

Comparison of Wireless Temperature Measurement and Infrared Temperature Measurement:

Infrared temperature measurement is a non-contact method, but it is highly susceptible to environmental factors such as dust and electromagnetic fields. In the case of high-voltage equipment, which is often located in dusty environments, the infrared temperature measurement sensor can be covered with dust, leading to significant changes in temperature readings. This can result in abnormal temperature readings, often displaying values several hundred degrees higher than the actual temperature, triggering false alarms.

Moreover, the limited space within switchgear makes it impractical to install infrared temperature measurement probes. The probe requires a certain safe distance from the object under test and needs to directly face the surface of the object. However, the wireless temperature measurement system is not affected by such limitations imposed by the switchgear’s physical structure.

In summary, while infrared temperature measurement is a non-contact method, its accuracy can be compromised by environmental factors and limited installation options within switchgear. On the other hand, wireless temperature measurement overcomes these limitations, offering accurate temperature monitoring without being affected by dust or the switchgear’s confined space.

Selection Model and Specification

Main Specifications

1. Working environment

Temperature:-20℃~+60℃

Humidity:≤95%RH

Altitude:≤3000m

2.Electrical parameters

Working power: AC200V(±10%), frequency50/60Hz

Dielectric strength:≥AV3000V

Insulation properties: ≥100MΩ

power consumption:≤8W

Anti-static interference:4000v

Anti-electromagnetic interference performance: Comply with the standard of IEC255-22

Early warning output: passive contact output, AC220V 5A

Alarm output: passive contact output, AC220V 5A

Load control output: passive contact output, AC220V 5A

Load capacity: double the working voltage, rated power resistive load AC220V 5A

3. Environmental temperature and humidity measurement range

Humidity measurement range: 0%RH~99%RH

Temperature measurement range: -19°C~99°C

4. Accuracy measurement

Environmental humidity measurement accuracy: ±3.0%RH

Ambient temperature measurement accuracy: ±1°C

Resolution: 1RH%, 1%

5. Data communication

Communication method: RS485

Communication protocol: ModBus

Communication baud rate: 9600bps

Data format: eight data bits, one stop bit, no parity

6. Temperature measurement parameters of contact/cable lap joint nodes

Contact capacity (maximum): four groups of twelve points

Sampling cycle: 2 times/second, emission cycle 90 seconds/time (isothermal condition)

Alarm event storage: ≤40 items

Contact/cable lap temperature accuracy: ±2°C

Data storage time: ≥10 years

Device function description

1. Contact/cable head temperature measurement function

- Real-time online monitoring of the temperature of multiple high-voltage contacts or cable joints at the same time

- The data detected by the system is displayed on the LCD screen. When the temperature of the high-voltage contact or cable joint rises to the set temperature value, the system will start the corresponding alarm function (the alarm indicator light is on, and the contact alarm output changes from normally open to for normally closed)

- High-voltage contact/cable joint warning and alarm temperature values can be set according to the needs of users

- High-voltage contact/cable joint temperature measurement data transmission method: wireless transmission

- Working principle: (two-level alarm output function)

Early warning output: When the temperature measured by the contact temperature measuring device is higher than the temperature measurement early warning value, the contact early warning output changes from normally open to normally closed (passive), and the corresponding panel warning indicator light is on;

When the temperature measured by the contact temperature measurement device is higher than the temperature measurement alarm value, the contact alarm output changes from normally open to normally closed (passive), and the corresponding panel alarm indicator light is on;

When the temperature measured by the contact temperature measuring device is lower than the temperature measurement alarm value, the contact alarm output changes from normally closed to normally open (passive), and the corresponding panel alarm indicator light is off. - Temperature measurement unit structure

It is composed of three parts: the main unit of the electrical contact wireless temperature measurement device, the temperature measurement transmitter module, and the temperature measurement receiver module. - Assembly principle

Installation of temperature measurement transmitter module (strap type or ring type): install the transmitter module on the busbar of the switch cabinet inlet room (or outlet room) or the static contact box of the circuit breaker, and the installation method is bundled or Bayonet mount.

Note: watch strap power switch, “on” is open, “off” is closed.

Temperature measurement transmitter module: the color is red, yellow, green (busbar installation), the static contact box installation transmitter module color is orange: the incoming room is (A1, B1, C1), the outgoing room is (A1, B2, C2).